Tire Buffer Wheel Abrasiveness Coarse Buffing Wheel

In the video, it was recommended to use a tire buffer wheel to smooth out the area around the puncture. I'm linking this here for reference.

Safety Wire Tool

It was suggested that I safety wire the exhaust header bolts so they don't fall out again. I'll pick up a tool similar to this.

Tire and Tube Patch Auto Repair Stitcher Tool

Stitcher tool used to roll over the patch to smooth out any bubbles. I can probably use some piece of hard plastic to accomplish the same effect.

Craftsman Bench Grinder with Wire Wheel

Duncan gave me this bench grinder with the wire wheel attachment and demonstrated how well it can clean up old bolts.

As of this writing there doesn't seem to be this exact model available on Amazon but there is a 6" one. The wire wheel attachment is sold separately.

OEMTOOLS 24804 Mobile Parts Washer

Tom Cutter of Rubber Chicken Racing Garage told me once, "If you don't clean your parts you're just an amateur."

So I decided to finally get a parts cleaner. A I am fairly space constrained in my garage so this mobile smaller parts washer turned out to be a very nice solution. I was skeptical at first, but I find I use this quite often. I did learn the hard way, however, not to use it to clean parts covered in mud. Wash muddy parts off with a hose first before using the parts cleaner.

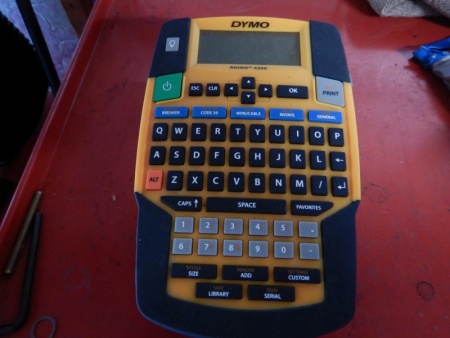

DYMO Rhino 4200 Industrial Label Maker

When I take something apart, I like to use labels to mark how things should go back together. When I take a connection apart, I mark both parts. This way I am less likely to make an error on reassembly.

I had tried consumer grade label makers but the problem was that the labels would degrade over time or when exposed to weather.

This label maker using vinyl labels does not suffer from that problem. It's expensive, but in my use case has proven to be a very valuable addition to my tool collection.

Kendon Folding Stand-Up ATV Motorcycle Table Lift

Because I am limited with the amount of space I have, I decided to try this Kendon folding lift. It's been a few years since I've gotten mine and looking at Amazon it looks like they may have made some minor changes to it.

My only real complaint about the lift has to do with the attachment points moving as you raise and lower the lift, requiring you to adjust the tension on any straps you have.

But I can easily overlook that based on the fact that this folds up and is easily stored out of the way.

K100RS Clutch Alignment Tool

I bought one of these when I had my transmission redone by Rubber Chicken Racing Garage back in 2013. My understanding is that there are ways around buying the tool but I have not tried them.

Transmission Removal Guide Pins

In order not to bend the clutch plunger rod when taking the transmission off they recommend using some guide pins. I ended up just making some from some stock I bought at Home Depot.

Rear Main Seal Driver Tool

I also bought the recommended rear main seal driver tool which is modified so that the seal sits .5mm further out. This lets the seal mate up with fresh metal.

I think I got it at Bobs and a tech there did the modification for me but I don't have a link handy.