PROJECT: The Great BMW K100RS 16V Engine Swap Project of 2019

This is an open project.

This project is ongoing.

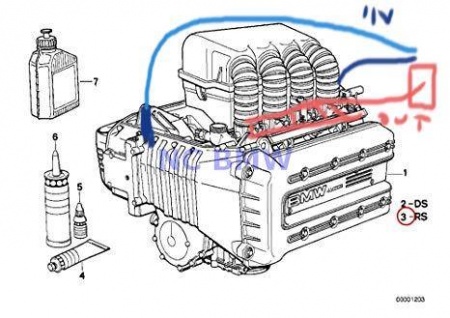

"Pull the boot on the throttle pot down, then probe the White/Pink wires terminal with something like a straightened paper clip. Connect the positive lead to the paper clip, and the neg lead to a convenient ground. Turn the ignition to on. You should see 35 mv-to 38mv. If not, loosen the screws that hold the pot, and slowly move the pot until you reach the desired reading."

"It's pretty simple. The engine should have fairly fresh oil in it, and the throttle body synch fairly close. Connect the gas analyser to power and let it warm up for 1/2 hour. While you wait for it, take the bike for a ride to get it warm. Insert the probe as far into the exhaust as it will reach, and wait for the readout to stabilise. It will change a bit constantly. You want a CO of at least 2.5%. I prefer 3.0-3.5. Turn the pot screw in to lean it, and out to richen. When you're satisfied, ride the bike again and re-check."

Tomorrow we venture on to preparing and mounting the rear cowling and wiring up brake and tail lights and turn signals.

After that it’s spark plugs, wires, brake fluid, and coolant fluid … etc … then we add the battery and ecu and abs boxes and see if the magic smoke leaks out.

Because we've never done steering bearing races before we decided to practice on the spare frame before attempting it on my frame. To our surprise the correct steering bearing race puller was in my bottom drawer.

buffalohad given it to me back in /2007/!

buffalohad given it to me back in /2007/!We did successfully pull the race out. It took /MUCH/ more force than expected but we did not damage anything.

The next time we'll pull the bottom race out as more practice and then move our attention to start reassembly.

This should be the last thing on the list that we have not done before. Fingers crossed.

Spare Steering Stem Removal and Initial Bearing Race Removal

Having never pulled a bearing race out of a steering head, we decided it best to practice on the donor bike frame first.

buffalo's boat is sorted and sailing school is behind me, as I had promised, we started on the reassembly project. Tim came by and his help was invaluable.

buffalo's boat is sorted and sailing school is behind me, as I had promised, we started on the reassembly project. Tim came by and his help was invaluable. Trying to remember/figure out how all the wires run was a fiddly and time consuming process that needed to be done very carefully. I /think/ we have it correct but am prepared to go back in and redo it as many times as necessary until it's right.

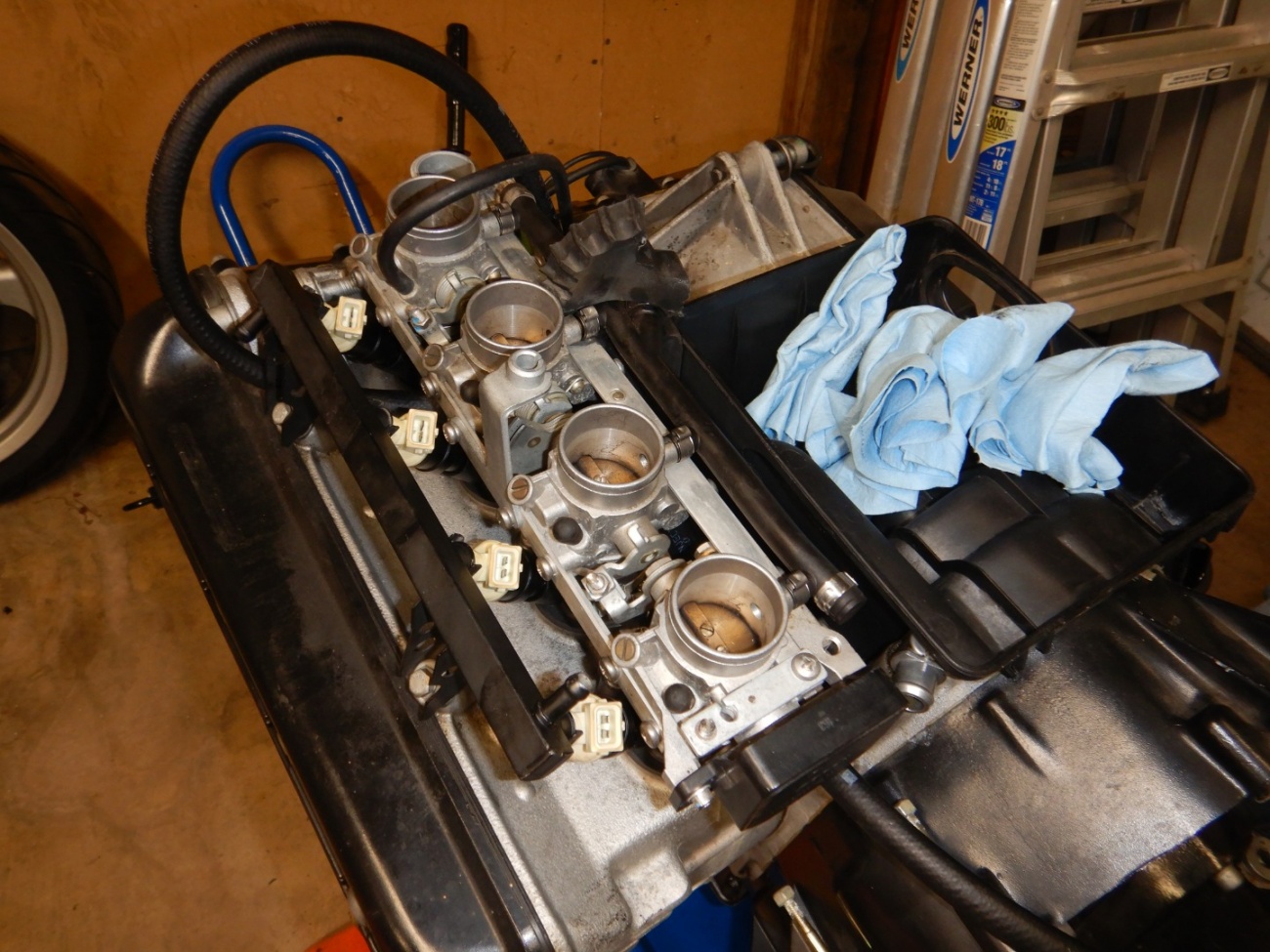

buffalo and I got a fair bit of work done yesterday. We cleaned up the throttle bodies and fuel rail and managed to get everything installed.

buffalo and I got a fair bit of work done yesterday. We cleaned up the throttle bodies and fuel rail and managed to get everything installed. Separately we made some progress on the crankcase breather modification to remove the "cyclonic separator" from the system. (see other project).

There's still some question about routing some of the new tubing but it seems like it's coming together.

We did determine that the steering head bearings are so bad as to be unsafe to ride so the head bearings will need to be done before the bike can be ridden.

I still need to figure out how to adjust the mixture given that I'm going to be mounting the freer flowing Remus exhaust.

Freshly serviced injectors from Mr Injector.

K100RS Crankcase Breather Modification

The "cyclonic separator" in my '92 K100RS 16V is well past dead. I've been researching various PCV valve solutions. This project encompasses that research.

K100RS 16V Steering Head Bearings Replacement

As part of the great engine swap project, I need to replace the steering head bearings on my '92 K100RS. I've never done this job before so this project is a place to collect all the parts, tools, notes, and info I need to learn how to do this job.

- the crankcase PCV modification.

- how to replace the steering head bearings

- how to correctly adjust the mixture for the Remus exhaust and balance the throttle bodies.

The rest "should" be relatively straight forward.

October 6 2019 - Reassembly begins

We bolted on the rear wheel and then got the bike lift under the drive-train and supported it. This allowed us to move the A-frame to the side. We then proceeded to clean parts and polish some bolts. I had failed to torque a few bolts which I addressed while Duncan worked at the wire wheel to clean some bolts. We bolted on the lower air box after cleaning it along with the cooling system adapter and the intake manifolds.